What is Gravure Printing?

Features of Gravure Printing

Gravure printing is the most widely used printing method in the print manufacuring industry. It is a kind of intaglio printing and masters expressing vibrant colors. It is most commonly used for flexible packaging (food and consumer industry), construction lining material (aluminum, titanium...etc.), various plastics and paper, as well as tubing

> Gravure printing machine production Cases

|

|

Gravure

|

|

Did you know?

In the early 19th century gravure printing was called art printing. Magazine advertisements, which caught the eye of many readers due to the vibrant and sharp imaging marked the beginning of commerical gravure printing.

|

|

|

|

Banknote Printing

|

| Gravure printing is difficult to counterfeit and is widely used in banknote printing in many countries. |

|

Commonly Used Substrates

|

|

| Film/Vinyl printing (Food packaging) |

| Woodgrain printing for wallpaper, furniture, and other building materials |

| Art books/ photo albums |

| Paper (thin paper, paper cups, tobacco...etc.) |

| Metal Foil |

| Disposable diaper...etc. |

|

I also want to read it.

> What is flexographic printing?

Cylinder Engraving for Gravure Printing

One of the great features of Rotogravure printing is its product of sharp quality imaging. The vast gradation of colors is made possible by the denisty and width of the engraving and the thickness of the ink. Moreover, it has durability with the chrome plated cylinders which allows high speed printing and mass production.

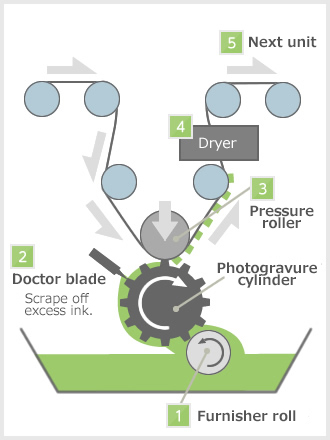

Flow of Gravure Printing

For gravure printing, the following process is repeated:

|

|

The funisher roll is immersed in the ink reservoir and fills the cell indentation (engraving) of the plate surface with ink. |

|

|

The doctor blade scrapes the cylinder and removes ink from the unprinted surface. |

|

|

The paper is sandwiched between the pressure roller and the gravure printing cylinder. Here the link is transferred from the cell to the paper. |

|

|

The paper is subjected to a dryer (as the paper has to be transferred to the next color unit and completely dried before absorbing the ink of another layer. |

|

|

The process repeats at the next color station. |

| Gravure printing press for soft packaging |

| SGX-1200-3S AP |

| Max. machine speed |

200m/min |

|

| Base material |

Plastic film |

|

|

> Gravure printing machine other than the above