ホーム > What is Flexographic Printing?

What is Flexographic Printing?

Features of flexographic printing

Flexographic printing is a letterpress printing method that uses a plate made of elastic material, (rubber, resin). The elastic, flexible plate creates a fine print image on various substrates including cardboard, cloth, paper and plastics.

> Flexographic Printing Machine Production Cases

|

|

|

|

Flexographic printing usage scene

|

|

I also want to read it.

> What is a gravure printing machine?

Prefabrication of flexographic printing

In contrast to the gravure printing method, the flexographic printing method creates a convex image on the printing plate and transfers the ink by placing the ink on the convex part.

For ink transfer, you can transfer uniformly by using a fine mesh engraved roll (anilox roll) without using a mill roll.

Printing plates can be printed on a wide range of materials such as paper, plastic, cloth, and rubber, because the inks used are extremely fluid with water based inks and UV inks and use flexible printing plates.

For ink transfer, you can transfer uniformly by using a fine mesh engraved roll (anilox roll) without using a mill roll.

Printing plates can be printed on a wide range of materials such as paper, plastic, cloth, and rubber, because the inks used are extremely fluid with water based inks and UV inks and use flexible printing plates.

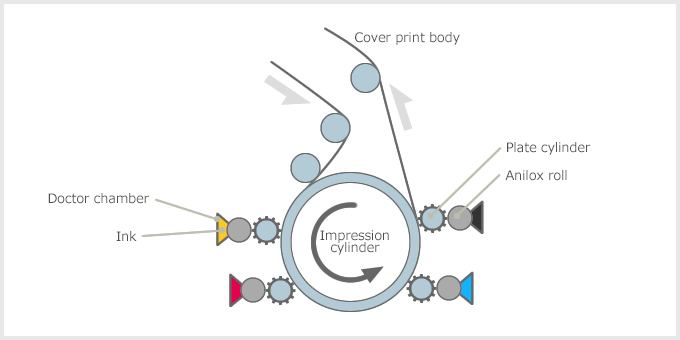

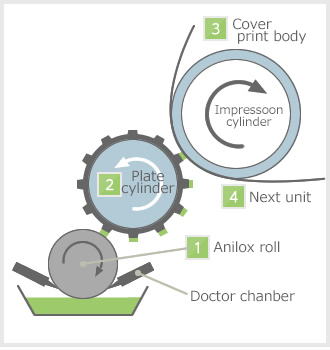

Flexographic printing process

For flexographic printing, the following steps are repeated (in the case of the doctor chamber method).

| The ink in the ink chamber is fed directly to an anilox roll (sculpture roll of fine mesh). |

| It transfers to a flexible printing plate made of rubber or resin. |

| Transfer with a low stamp pressure (kistacht) to the substrate between the flexo cylinder (anilox roll) and the impression cylinder. |

| Go to the next color unit. |

Sobu Machinery mainly adopts the center drum system