Japanese / English

What is Gravure Printing?

What is Flexographic Printing?

Build an efficient printing environment that meets your specific needs

At Sobu Machinery, we incorporate customer opinions in every process from inquiry to delivery, and sincerely respond to each and every request.

What is Gravure Printing?

Features of Gravure Printing

Gravure printing is the most widely used printing method in the print manufacuring industry. It is a kind of intaglio printing and masters expressing vibrant colors. It is most commonly used for flexible packaging (food and consumer industry), construction lining material (aluminum, titanium…etc.), various plastics and paper, as well as tubing

Gravure

Did you know? In the early 19th century gravure printing was called art printing. Magazine advertisements, which caught the eye of many readers due to the vibrant and sharp imaging marked the beginning of commerical gravure printing.

Banknote Printing

Gravure printing is difficult to counterfeit and is widely used in banknote printing in many countries.

Commonly Used Substrates

Film/Vinyl printing (Food packaging)

Woodgrain printing for wallpaper, furniture, and other building materials

Art books/ photo albums

Paper (thin paper, paper cups, tobacco…etc.)

Metal Foil

Disposable diaper…etc.

Cylinder Engraving for Gravure Printing

One of the great features of Rotogravure printing is its product of sharp quality imaging. The vast gradation of colors is made possible by the denisty and width of the engraving and the thickness of the ink. Moreover, it has durability with the chrome plated cylinders which allows high speed printing and mass production.

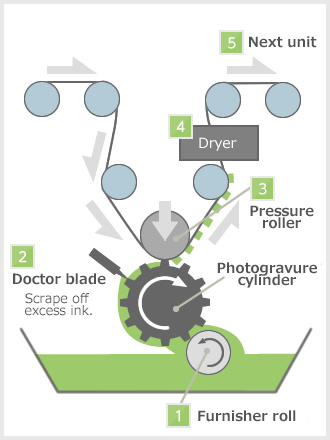

Flow of Gravure Printing

For gravure printing, the following process is repeated:

The funisher roll is immersed in the ink reservoir and fills the cell indentation (engraving) of the plate surface with ink.

The doctor blade scrapes the cylinder and removes ink from the unprinted surface.

The paper is sandwiched between the pressure roller and the gravure printing cylinder. Here the link is transferred from the cell to the paper.

The paper is subjected to a dryer (as the paper has to be transferred to the next color unit and completely dried before absorbing the ink of another layer.

The process repeats at the next color station.

What is Flexographic Printing?

Features of flexographic printing

Flexographic printing is a letterpress printing method that uses a plate made of elastic material, (rubber, resin). The elastic, flexible plate creates a fine print image on various substrates including cardboard, cloth, paper and plastics.

Good for the environment

Historically Flexographic Printing uses an Alcohol or Ester Based ink. Water Based Inks is a newer environmentally conscious printing method and is currently a growing trend in Europe.

Multifuctional use

It can print with low printing pressure, or it can be connected to another plate form such as offset printing or gravure printing, or it can be connected to a packaging processing apparatus (cutting, folding etc.)

Flexographic printing usage scene

Cardboard (direct printing / preprint)

Paper bag

Envelopes, notes, chopsticks bags

Liquid paper container (mainly milk carton)

Plastic bags, film bags

Hamburger wrapping paper

Disposable diapers etc.

Prefabrication of flexographic printing

In contrast to the gravure printing method, the flexographic printing method creates a convex image on the printing plate and transfers the ink by placing the ink on the convex part.

For ink transfer, you can transfer uniformly by using a fine mesh engraved roll (anilox roll) without using a mill roll.

Printing plates can be printed on a wide range of materials such as paper, plastic, cloth, and rubber, because the inks used are extremely fluid with water based inks and UV inks and use flexible printing plates.

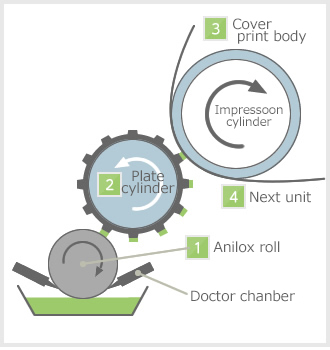

Flexographic printing process

For flexographic printing, the following steps are repeated (in the case of the doctor chamber method).

The ink in the ink chamber is fed directly to an anilox roll (sculpture roll of fine mesh).

It transfers to a flexible printing plate made of rubber or resin.

Transfer with a low stamp pressure (kistacht) to the substrate between the flexo cylinder (anilox roll) and the impression cylinder.

Go to the next color unit.

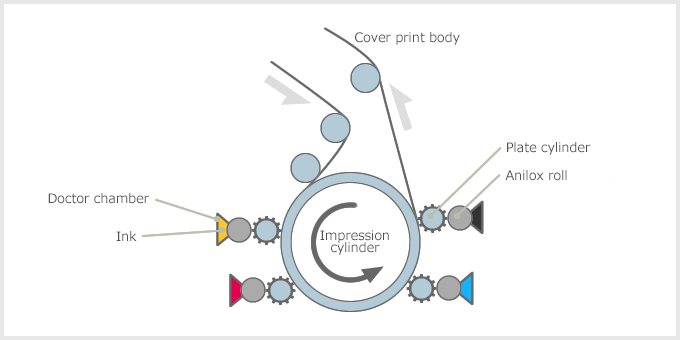

Sobu Machinery mainly adopts the center drum system

\ Please feel free to contact us /

Contact us by phone

Tel.0475-55-2135

Excluding Saturdays, Sundays, and holidays

8:30~17:30